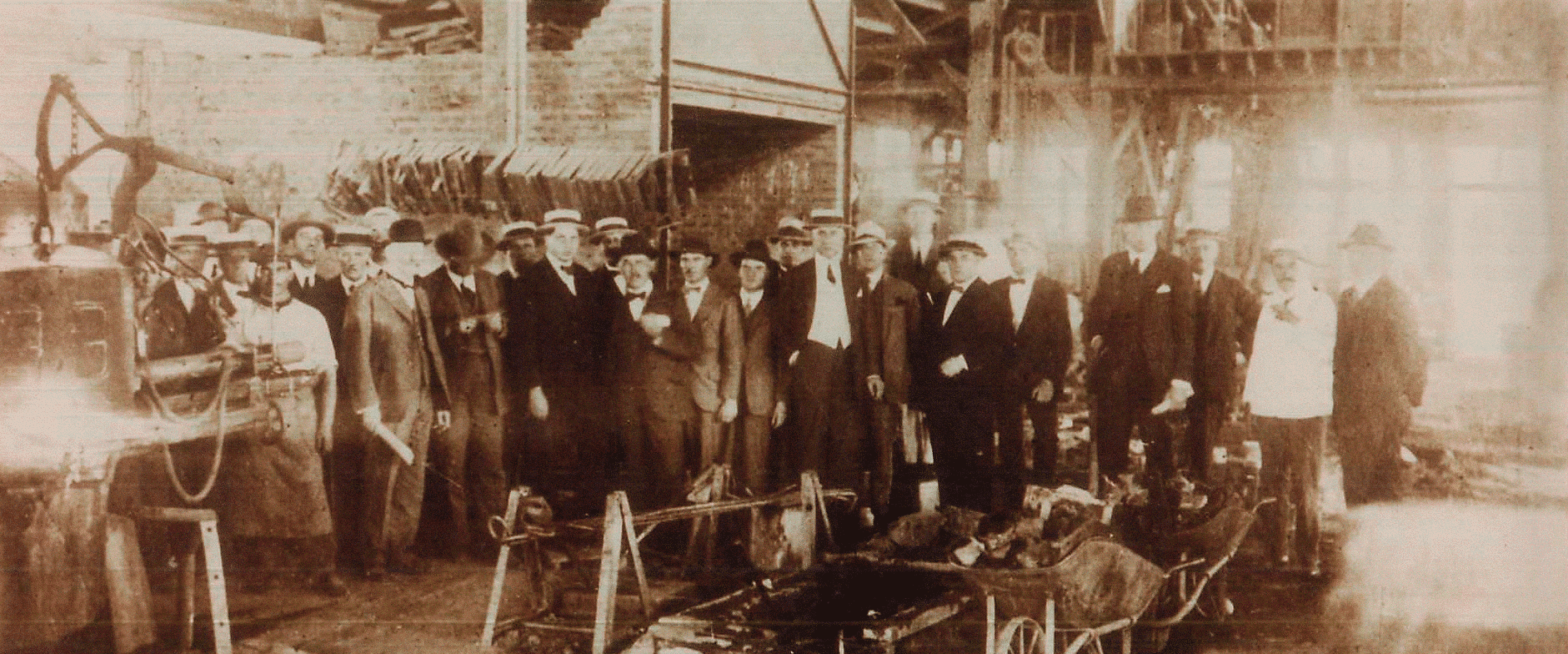

In Chile, Compañía Electrometalúrgica S.A., Elecmetal, was founded and installed the first electric arc furnace for steel casting in Latin America. At the same time, Minneapolis Electric Steel Casting (ME) began operations in the United States.

Began manufacturing molten material for “mineral grinding."

Purchased and installed new technology for the large-scale manufacture of forged balls for mining grinding.

Signed manufacturing license agreement with Electric Steel Co., ESC0, of Portland, Oregon (USA) to produce earthmoving spare parts.

Installed a vacuum casting system at our Duluth foundry in the United States.

Elecmetal expanded its metallurgical business by purchasing the assets of ME International and ME West Castings, inheriting the experience and know-how of ME International along with two modern foundries located in the states of Minnesota and Arizona.

ME Elecmetal purchases 60% of Fundición Talleres from Codelco, then the remaining 40% in 2008. This created the basis for the future Rancagua project.

Esco Corp. (USA) and Elecmetal entered into a Joint Venture and created ESCO Elecmetal, a subsidiary located in Colina, Chile, which manufactures steel spare parts for earthmoving equipment to supply the local and export markets.

ME Elecmetal and Longteng Special Steel Co. (China) form a 50/50 Joint Venture named "ME Longteng Grinding Media (Changshu)" to build a modern plant for the manufacture of more than 400,000 t/year of forged balls for the Mining Industry. The Early Alert was created and began providing 3D laser services and advanced non-destructive techniques for structural analysis of mining equipment and infrastructure.

Official inauguration of our grinding ball plant in Changshu, China as well as our Colina Plant in Chile where we manufacture wear elements for earth works. The company invested US$ 18 million in expanding two US foundries in Duluth, Minnesota and Tempe, Arizona.

We launched ME FIT System and became the first company to provide a comprehensive solution for the communition stage in mining. This same year we began operating a new modern foundry in Changzhou, China.

Our Rancagua Plant (formerly Fundición Talleres) underwent a major US$92-million overhaul.

Our new grinding ball plant began operations in Zambia.

We launched the ME Digital Lab, the company's technology arm that combines our extensive industry knowledge with emerging digital technologies as enablers of innovative and disruptive solutions for the mining market.