ME FIT Programs

We offer integral and technical solutions to help our customers tackle the unique challenges at each mining operation and to positively impact priority KPIs: tons per hour, safety management, availability and maintainability of equipment, risk prevention, among others.

We design solutions to help our customers achieve their goals by combining crusher wear parts with technology tools, advice, training and monitoring — all of which allow us to create value in our customers’ processes.

Products and services

Once the liner is used by the client in its operation, the worn part is scrap or waste in the clients’ warehouses, which accumulates over time.

This, added to the new provisions of the REP (Extended Producer Responsibility) Law, which defines obligations for industries regarding their production processes and how to manage waste in an integrated manner.

Customers can now pay for another actor in the chain to manage and/or dispose of their waste.

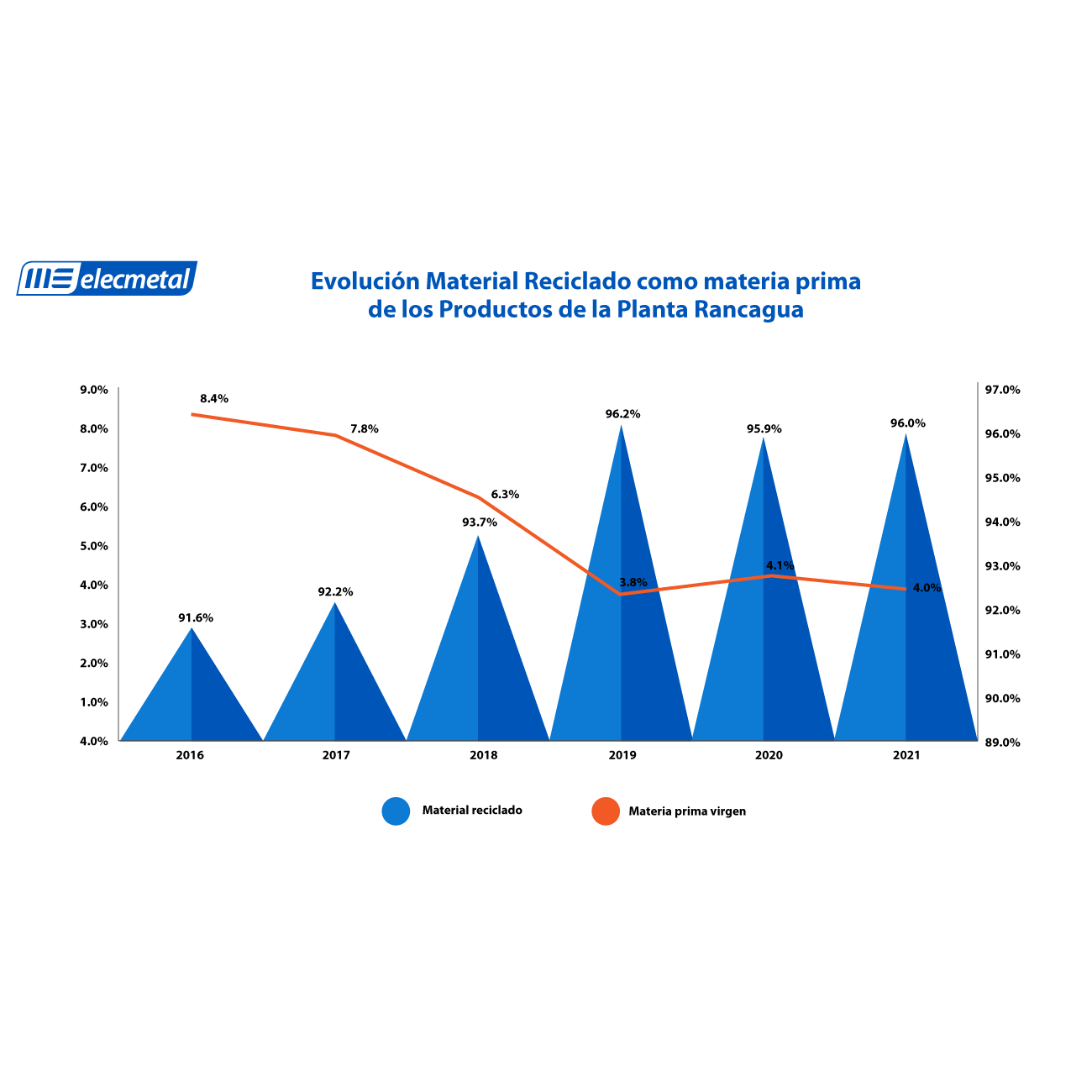

Since 2016, the operations area, together with other support teams, has sought to increase the circularity of the products we develop. To this end, we have progressively integrated recycled raw materials in the different products developed locally, as is the case of steel liners.

We began by identifying the composition of these products, once used by mining customers. The result of the research was to understand that once these components were implemented in the mining processes, they still had 95% of material that could be reused.

Therefore, the supply area monitors the purchases made by the customers, and then buys and recirculates the scrap and reconverts it into a new liner.

With this initiative, all of our customers contribute to circularity:

ME FIT Programs

Products and services

Mining 4.0

Your message will be reviewed by our area managers and they will contact you shortly

Keep up to date with the latest news from ME Elecmetal.