ME FIT Programs

We offer integral and technical solutions to help our customers tackle the unique challenges at each mining operation and to positively impact priority KPIs: tons per hour, safety management, availability and maintainability of equipment, risk prevention, among others.

We design solutions to help our customers achieve their goals by combining crusher wear parts with technology tools, advice, training and monitoring — all of which allow us to create value in our customers’ processes.

Products and services

Elecmetal’s circular economy area was created in 2022 and has three objectives:

Regarding the polyfit plant, it is a unique solution in the national market, which allows the separation of steel from rubber through a plant. Thus, it is estimated that it is possible to recycle 2 thousand tons* of rubber per year.

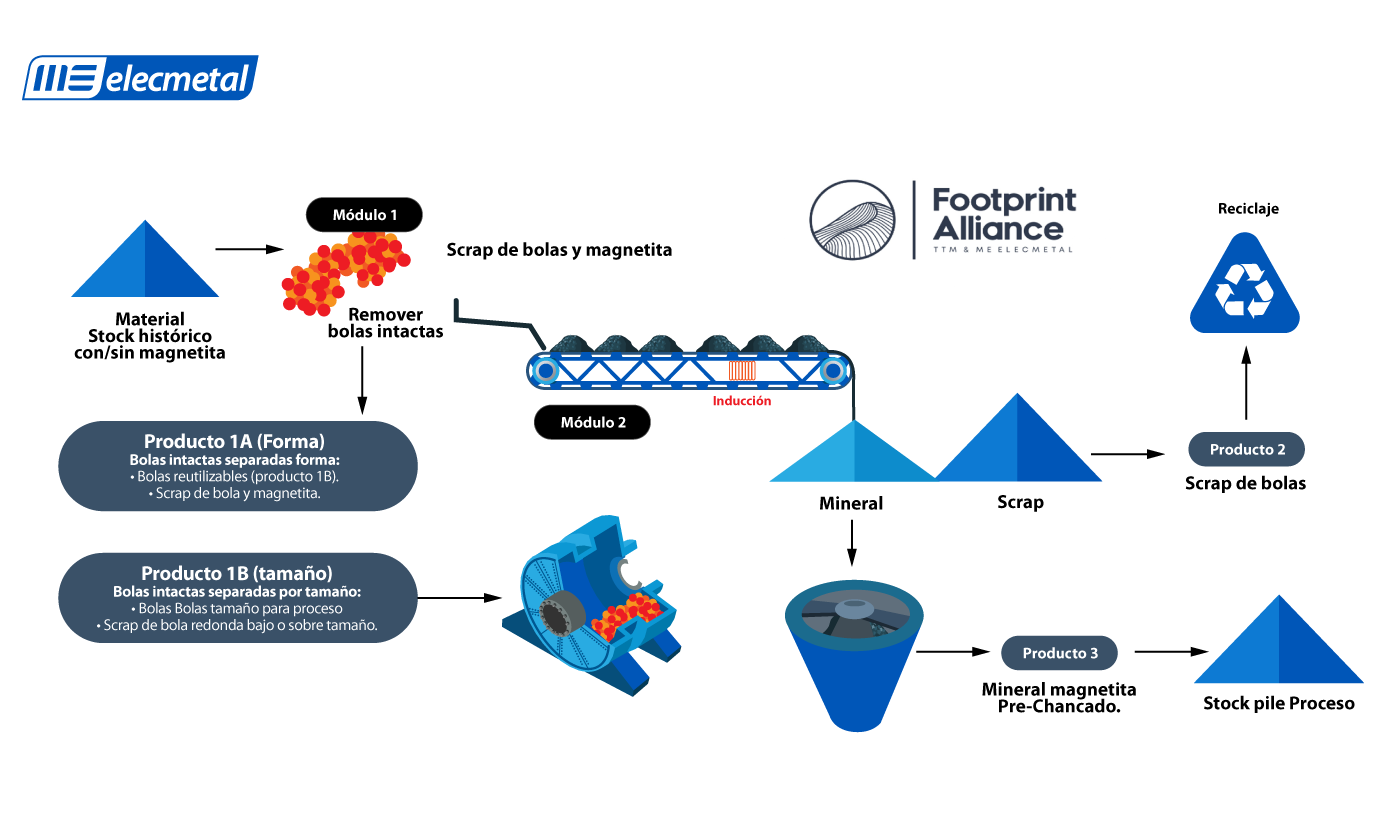

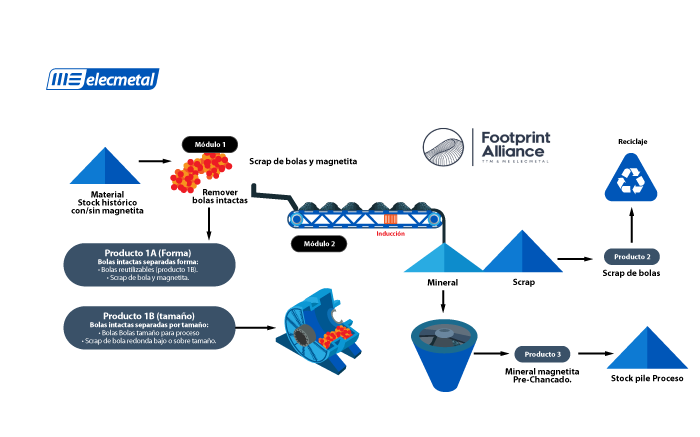

Regarding scrap separation, this is a plant that can differentiate between the magnetite (ore) and the ball that is discarded from the milling process. This initiative is in a test phase. The plant was installed in central Chile and is expected to be mobilized to our customers’ mining sites in the short term. It is estimated that the amount of waste to be recirculated could reach 80 thousand tons* per year, which can be sold to steel suppliers.

*Note: the estimates of tons to be recirculated in both cases will depend on the plant configuration and production capacity.

The initiative will benefit all of our customers who process copper, either concentrate or cathode:

ME FIT Programs

Products and services

Mining 4.0

Your message will be reviewed by our area managers and they will contact you shortly

Keep up to date with the latest news from ME Elecmetal.