ME FIT Programs

We offer integral and technical solutions to help our customers tackle the unique challenges at each mining operation and to positively impact priority KPIs: tons per hour, safety management, availability and maintainability of equipment, risk prevention, among others.

We design solutions to help our customers achieve their goals by combining crusher wear parts with technology tools, advice, training and monitoring — all of which allow us to create value in our customers’ processes.

Products and services

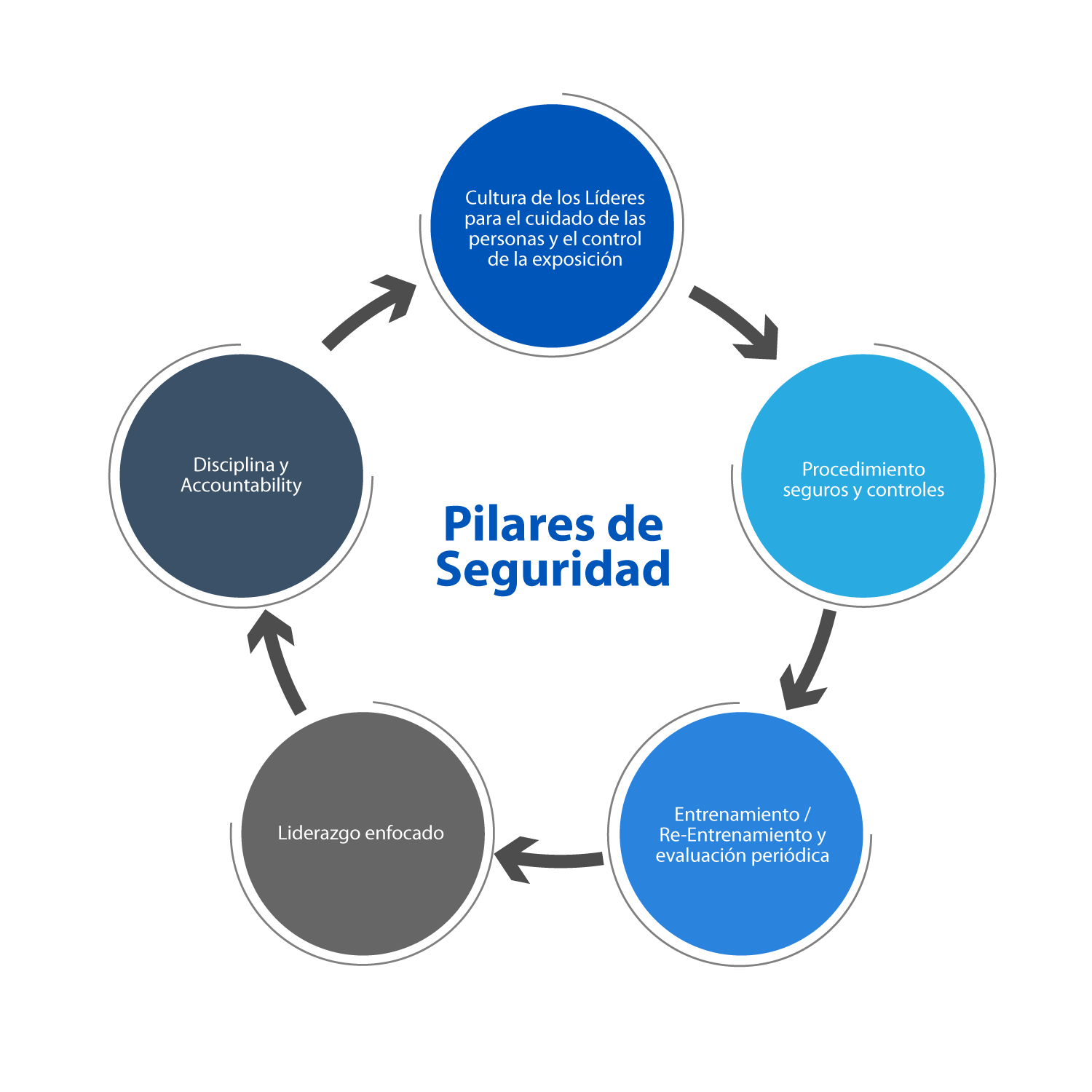

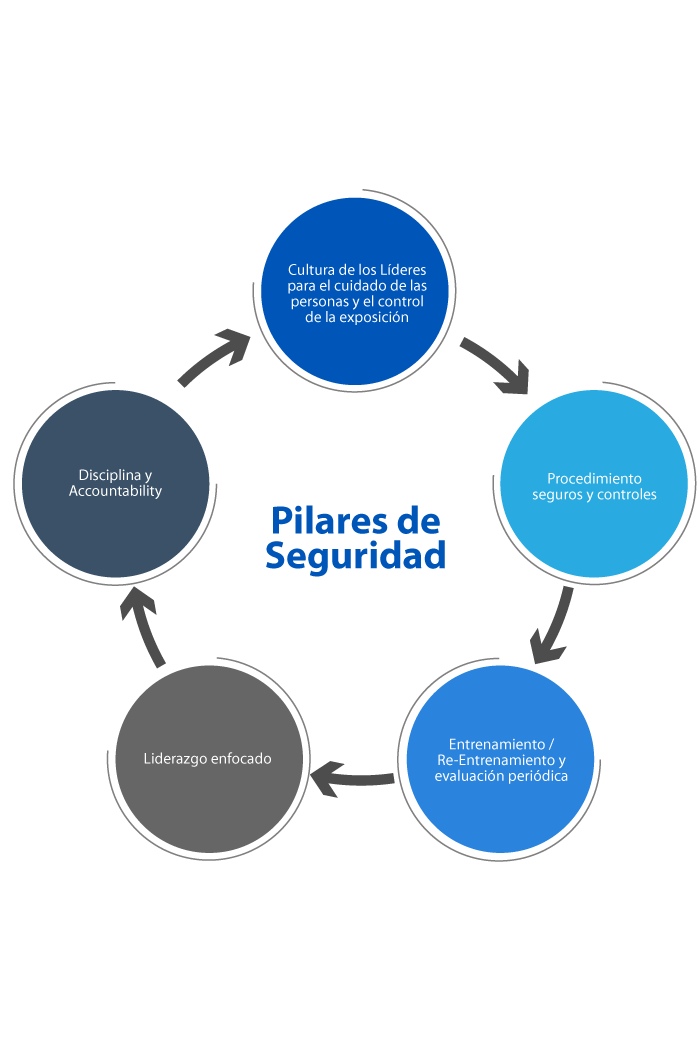

In order to work in a focused way, safety is understood in ME Elecmental through 5 work axes or pillars:

1. Discipline and accountabilitiy: responsibilities are clear regarding the actions that everyone must comply with and do to operate safely. It also integrates an area for leaders to have the opportunity to demonstrate the results obtained in their areas with respect to occupational health and safety management. It includes recognition activities and disciplinary measures in case there are repeated incidents or in case of an unsafe conscious action.

2. Safe procedures and controls: standardize the best known way to perform the work in terms of safety, quality and productivity, considering the variable of individual responsibility. Integrates review and improvements based on observations and shift checks.

3. Training: this is a standardized plan that provides concrete tools to understand and correctly execute the procedures and controls established for each activity. It integrates three variables: the role of the supervisor, the certification of the machinery and the permanent survey of the risks of the work in each position or workplace.

4. Safety culture and safe workers: its purpose is that all the company’s employees have safety first in all the decisions they have to make during their work activities. To this end, we work on leadership and behavioral safety programs at all levels of the company, in order to leverage the commitment of the work teams.

5. Focused leadership: this is associated with the role of the leaders in relation to the daily decisions of their work team, the working conditions, the behavior of their team and the incidents reported. In other words, the safety issue is not overlooked, on the contrary: it is stopped and resolved before continuing the operation if necessary. In this context, feedback and coaching appear as the basic tools to be able to modify behaviors, hand in hand with recognition.

All of the above is worked through the tools of the Lean Manufacturing strategy.

During the past year and this year the main focus has been on working with leaders, through the implementation of a leadership program that seeks to reduce exposure to hazardous situations and conditions and the improvement of the safety culture.

This is a program that seeks to reinforce aspects of team bonding to establish safe behaviors and conditions. The program began to be implemented during the year 2022 with three focuses:

This program is in addition to the behavior-based safety program implemented for the past 5 years.

Like everything else, we seek to improve zero harm culture, During the year 2023, a Safety Culture measurement will be conducted.

Continue to reinforce the safety culture aspects within ME Elecmental, impacting on accident and occupational disease indicators.

With the implementation of this model we seek to advance towards a Zero Harm Culture to people, in all the company’s activities, considering three indicators:

We have involved all the contractors that work at our sites throughout the country, with whom we work systematically to improve our results.

ME FIT Programs

Products and services

Mining 4.0

Your message will be reviewed by our area managers and they will contact you shortly

Keep up to date with the latest news from ME Elecmetal.