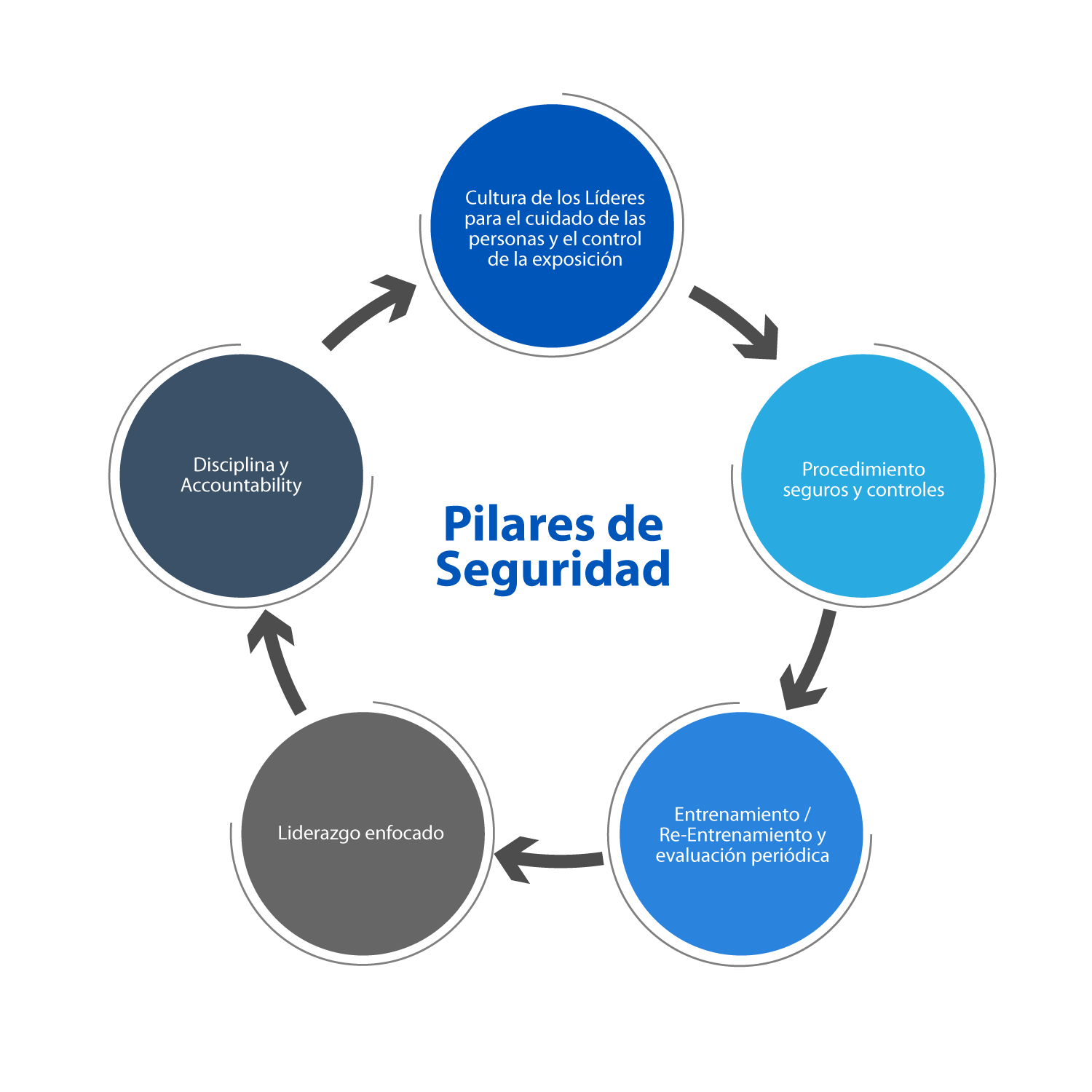

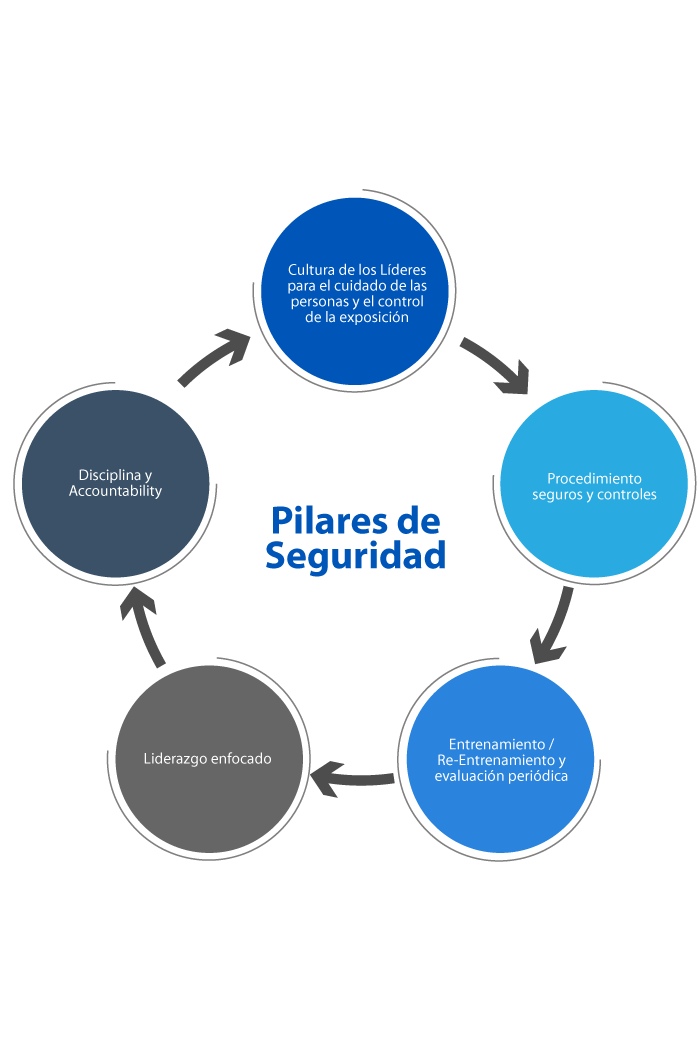

During the past year and this year the main focus has been on working with leaders, through the implementation of a leadership program that seeks to reduce exposure to hazardous situations and conditions and the improvement of the safety culture.

This is a program that seeks to reinforce aspects of team bonding to establish safe behaviors and conditions. The program began to be implemented during the year 2022 with three focuses:

- Safety contacts between leaders and workers

- Work sessions with teams to reinforce behaviors and work standards

- Physical risk inspection

- Coaching

This program is in addition to the behavior-based safety program implemented for the past 5 years.

Like everything else, we seek to improve zero harm culture, During the year 2023, a Safety Culture measurement will be conducted.